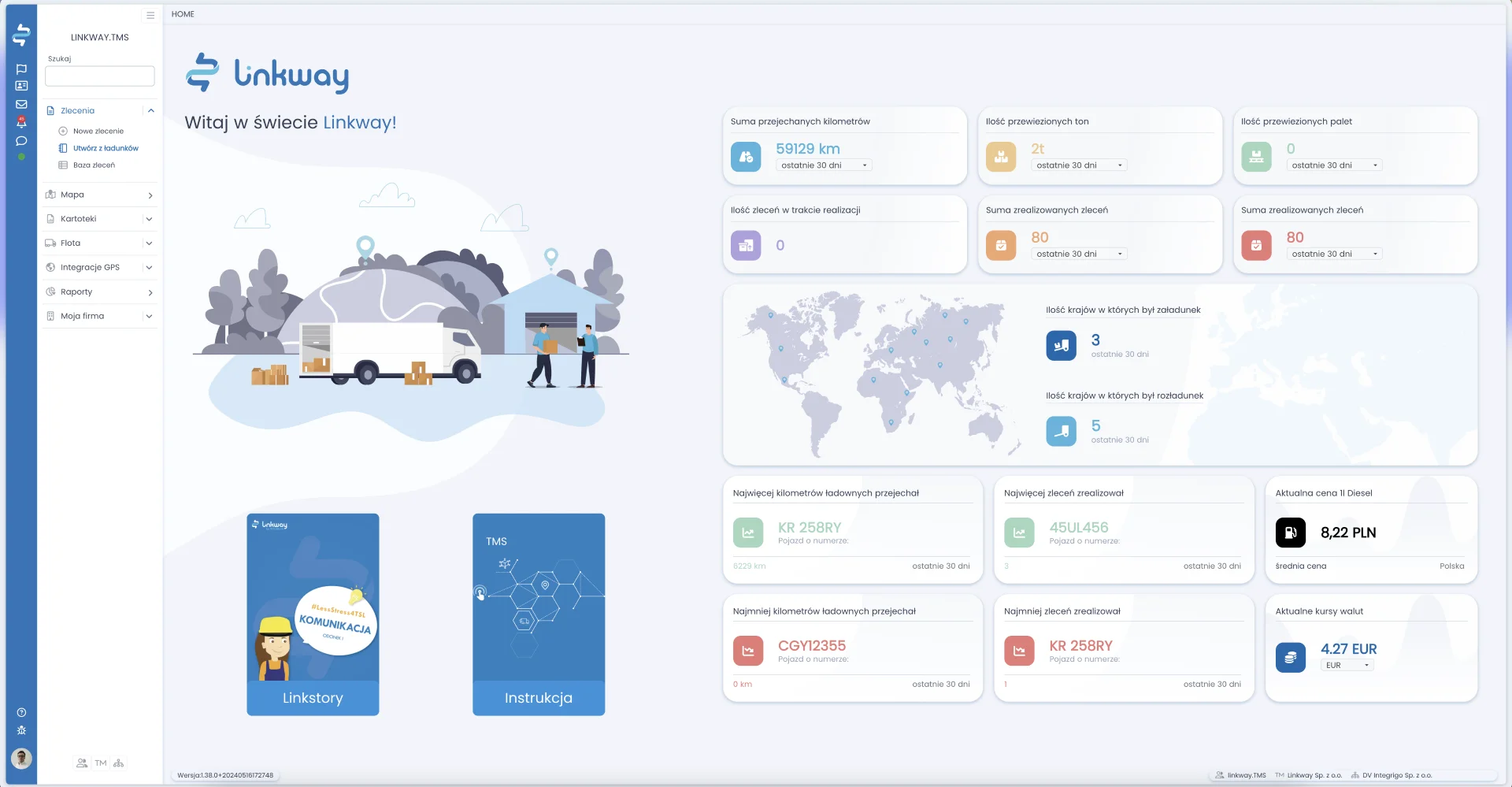

linkway. WMS

Zarządzanie operacjami magazynowymi. Dokładność ewidencji danych.

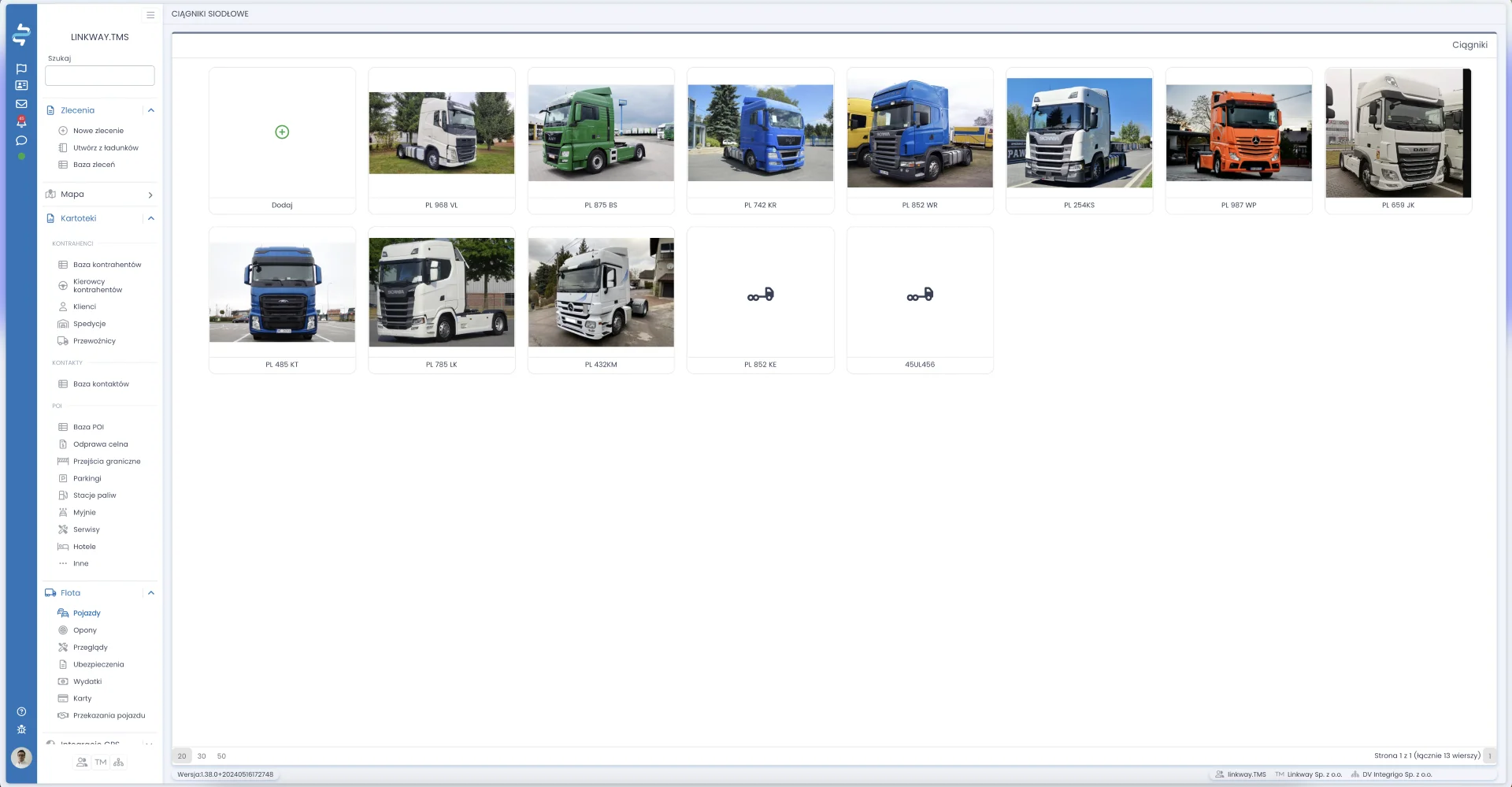

Program magazynowy

Skanery i kody kreskowe

Aplikacja linkway.WMS jest nowoczesnym narzędziem wspierającym zarządzanie magazynem. Pozwala ona na efektywne wykorzystanie terminali mobilnych i czytników kodów kreskowych, co znacząco przyspiesza operacje magazynowe. Dzięki temu system zapewnia minimalizację błędów i optymalizację pracy magazynierów. Wprowadza funkcjonalność kompletacji zamówień, gdzie magazynier jest kierowany zdefiniowaną trasą zbiórki. Taka organizacja pracy umożliwia zaoszczędzenie czasu przy realizacji zleceń wydania. Terminal aplikacji może funkcjonować zarówno w sieci wewnętrznej, jak i zewnętrznej, na przykład wykorzystując technologię LTE.

Program magazynowy linkway.WMS umożliwia integrację z innymi systemami, na przykład z oprogramowaniem klasy ERP. Integracja ta może odbywać się na dwa sposoby: statyczny, poprzez import i eksport plików, lub dynamiczny, wykorzystując połączenie API lub serwer FTP. Dzięki temu aplikacja jest elastyczna i dostosowana do różnorodnych potrzeb przedsiębiorstw.

Przekazywanie danych odbywa się jedynie między powiązanymi ze sobą użytkownikami platformy Linkway. Jest to proces, w którym użytkownicy przesyłają informacje między sobą za pośrednictwem systemu Linkway. Dzięki temu możliwe jest udostępnianie istotnych danych dotyczących realizowanych zleceń, pojazdów czy lokalizacji w celu efektywnego zarządzania flotą lub logistyką.

Dane GPS o zrealizowanych zleceniach mogą być przechowywane w systemie nawet przez 365 dni. Oznacza to, że informacje o lokalizacji pojazdów oraz ich trasy są rejestrowane i archiwizowane przez długi okres czasu. Jest to przydatne zarówno dla monitorowania działań floty w przeszłości, analizy wydajności, jak i dla celów administracyjnych oraz prawnych, gdy konieczne jest udokumentowanie trasy lub przebiegu zleceń.

Udostępnienia są tworzone indywidualnie dla każdego użytkownika panelu Linkway. Oznacza to, że użytkownicy mogą ustalać parametry udostępniania danych, takie jak zakres informacji czy okres dostępu, dostosowując je do swoich potrzeb i preferencji. To zapewnia elastyczność i kontrolę nad udostępnianymi danymi, co jest istotne w przypadku różnorodnych scenariuszy związanych z zarządzaniem flotą lub logistyką.

Udostępnione auto może być monitorowane cały czas w podanym zakresie dat lub tylko podczas realizacji zlecenia transportowego. To umożliwia skupienie się na określonych momentach lub wydarzeniach związanych z pojazdem, co jest szczególnie przydatne w celu śledzenia przemieszczania się pojazdu w czasie rzeczywistym lub analizy jego działalności w określonym okresie.

Dodatkową funkcją jest mailowe potwierdzenie udostępniania pojazdu przez właściciela pojazdu, w każdej chwili właściciel może wycofać udostępnianie. Jest to mechanizm zapewniający bezpieczeństwo i kontrolę nad udostępnianiem danych. Użytkownik może otrzymać potwierdzenie mailowe, informujące go o udzieleniu dostępu do swojego pojazdu, co zwiększa przejrzystość i świadomość związane z udostępnianiem informacji.

Możliwe jest też określenie, jakie dane zostaną przekazane: tylko dane lokalizacyjne auta czy wybrane dane telematyczne (np. temperatura chłodni). Użytkownik może precyzyjnie ustawić, jakie informacje chce udostępnić, dzięki czemu może kontrolować przekazywane dane zgodnie z potrzebami swojej działalności lub wymogami związanymi z zarządzaniem flotą.

Udostępnianie danych między użytkownikami systemu jest proste i czytelne, ale przede wszystkim wspomaga operatora w automatyzacji udostępniania na zasadach przez niego ustalonych. Dzięki temu procesowi użytkownicy mogą efektywnie i szybko przekazywać istotne informacje o zleceniach, pojazdach lub lokalizacji, co przyczynia się do usprawnienia zarządzania flotą lub logistyką.

Dlaczego warto?

Integracja systemów

Oprogramowanie linkway.INTEGRATOR wspiera proces integracji z różnymi systemami ERP i TMS, takimi jak SAP. Umożliwia to dynamiczne i statyczne aktualizowanie zmian we wszystkich powiązanych aplikacjach. Dzięki temu, dane w każdym oprogramowaniu są zawsze aktualne i spójne. Jest to kluczowe dla efektywnego zarządzania procesami biznesowymi w nowoczesnych organizacjach. Ponadto, linkway.INTEGRATOR zapewnia łatwość obsługi i wysoką wydajność, co przekłada się na lepszą organizację pracy i oszczędność czasu. Wspomaga to efektywne zarządzanie przedsiębiorstwem w dynamicznie zmieniającym się świecie Internetu.

Personalizacja funkcji

Funkcja aplikacji linkway.INTEGRATOR zapewnia personalizację dzięki zaawansowanym technologiom. Nasza autorska platforma wykorzystuje Microsoft .net oraz bazę Microsoft SQL. Dodatkowo, zastosowanie standardów HTML5, CSS3, Vue zwiększa jej elastyczność. Ta elastyczność jest kluczowa podczas wdrażania systemu. Umożliwia ona dopasowanie go do indywidualnych potrzeb każdej firmy. Personalizacja w linkway.INTEGRATOR oznacza tworzenie rozwiązań, które odpowiadają na wszystkie wymagania klienta. Nasze podejście skupia się na dostosowaniu funkcji do specyfiki działalności klienta. Zapewniamy, że każda funkcja aplikacji jest spersonalizowana i efektywna. W linkway.INTEGRATOR priorytetem jest zaspokajanie indywidualnych potrzeb firm w Internecie.

Kontrola informacji

Linkway.INTEGRATOR to zaawansowana aplikacja, która efektywnie kontroluje przepływ informacji. Dzięki niej, udostępniane dane są ściśle monitorowane. W rezultacie, użytkownicy otrzymują dostęp tylko do tych informacji, które są dla nich niezbędne. Aplikacja ta zapewnia bezpieczeństwo i precyzję w zarządzaniu danymi. Jest idealna dla firm ceniących sobie kontrolę i efektywność w dostępie do informacji w Internecie.

Obniżenie kosztów

Optymalizacja zarządzania w firmie dzięki aplikacji linkway.INTEGRATOR. Aplikacja ta umożliwia centralizację danych, co znacząco przyczynia się do efektywniejszego zarządzania. W rezultacie, firmy mogą obniżać koszty operacyjne. Centralizacja informacji w linkway.INTEGRATOR ułatwia podejmowanie szybkich decyzji biznesowych. Dzięki temu, zarówno zleceniodawcy, jak i zleceniobiorcy, odnoszą korzyści. Efektywność zarządzania procesami biznesowymi wzrasta, co bezpośrednio wpływa na zyski firmy. Wykorzystanie linkway.INTEGRATOR to krok w stronę nowoczesnego, kosztoefektywnego modelu biznesowego.

Czuj się bezpieczenie

Aplikacja linkway.INTEGRATOR zapewnia wysoki poziom bezpieczeństwa. Używamy zaawansowanych protokołów SSL do szyfrowania danych. Pozwala to na ochronę informacji przesyłanych przez Internet. Dzięki integracji z firmową domeną, jaką jest Active Directory, zyskujesz kontrolę nad kontami użytkowników. Zarządzanie uprawnieniami i hasłami staje się łatwe i bezpieczne. Wybierz linkway.INTEGRATOR, by zabezpieczyć swoje dane w cyfrowym świecie.

Prosta obsługa

Aplikacja linkway.INTEGRATOR oferuje intuicyjną obsługę, która znacząco ułatwia pracę z systemem. Nowoczesne rozwiązania zapewniają sprawne poruszanie się po różnorodnych funkcjach oprogramowania. Interfejs użytkownika jest przyjazny i ergonomiczny, co przekłada się na wygodę korzystania. Dzięki temu użytkownicy mogą efektywnie wykorzystywać pełen zakres możliwości aplikacji. Internet pełen jest przykładów zadowolonych użytkowników, którzy cenią sobie prostotę i funkcjonalność linkway.INTEGRATOR.

Wybrane funkcje aplikacji linkway.INTEGRATOR

Monitoring pojazdów

linkway.INTEGRATOR pozwala na przejrzyste, ciągłe monitorowanie własnych, otrzymywanych oraz udostępnianych aut na bieżąco. Wszystkie trasy są widoczne na mapie.

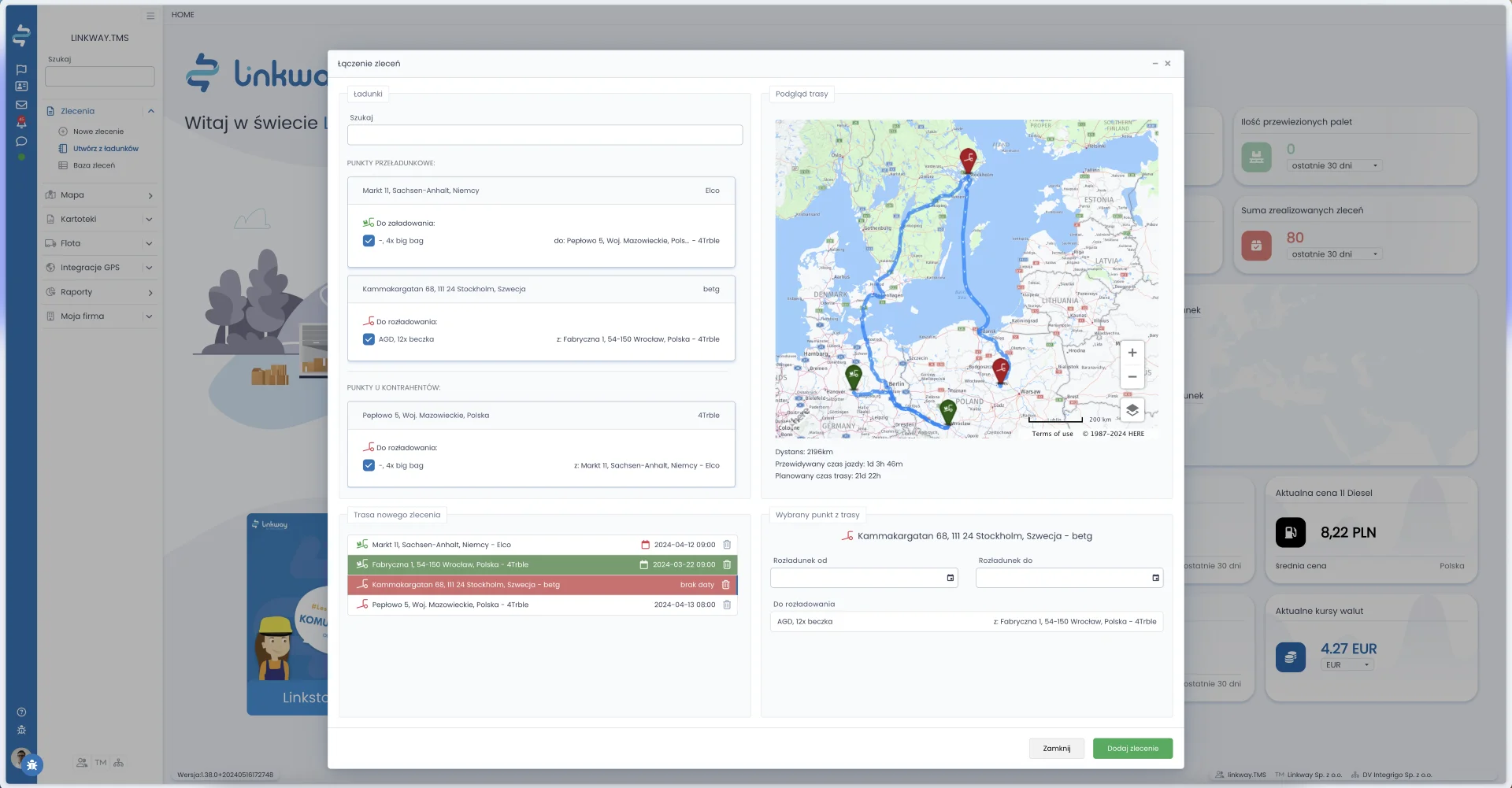

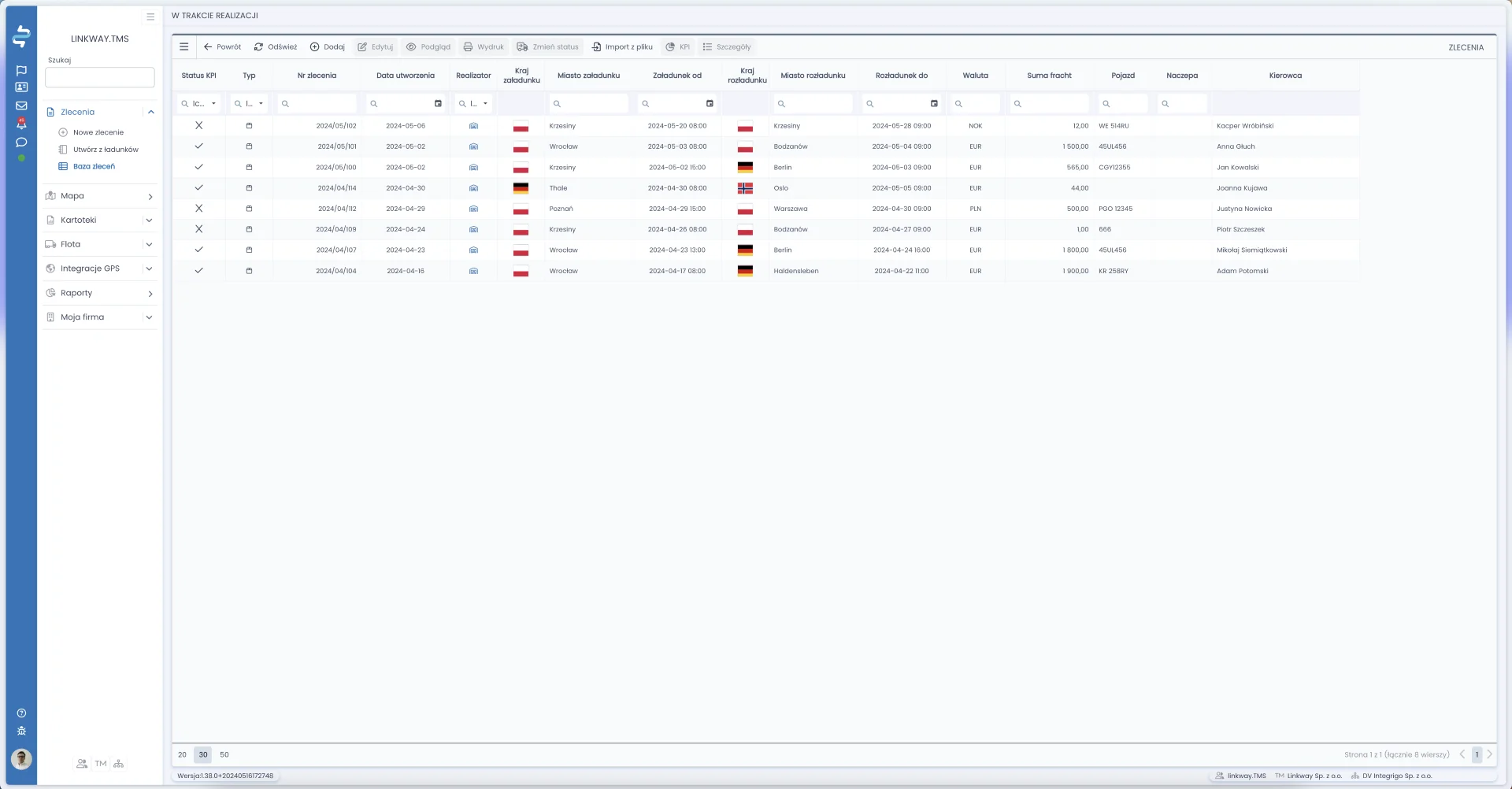

Zlecenia

Lista wszystkich zleceń dostępna jest z głównego panelu. W szybki sposób otrzymuje się dane na temat zleceń importowanych oraz monitorowanych z podziałem na realizowane, zakończone odrzucone oraz potwierdzone.

Analiza tras

Poprzez platformę można przeglądać monitorowane transporty oraz gromadzone dane udostępniane podczas każdego etapu przewozu asortymentu. Analizy dotyczące transportów przegląda się według: konkretnego kontrahenta, zlecenia i numeru rejestracyjnego.

Statystyki

linkway.INTEGRATOR to gromadzenie najważniejszych danych w jednym miejscu z podziałem na różne kategorie. Można zapoznawać się ze statystykami dotyczącymi przejechanych kilometrów, monitorowanych zleceń, ilości aut, dostawców GPS, podwykonawców i klientów.

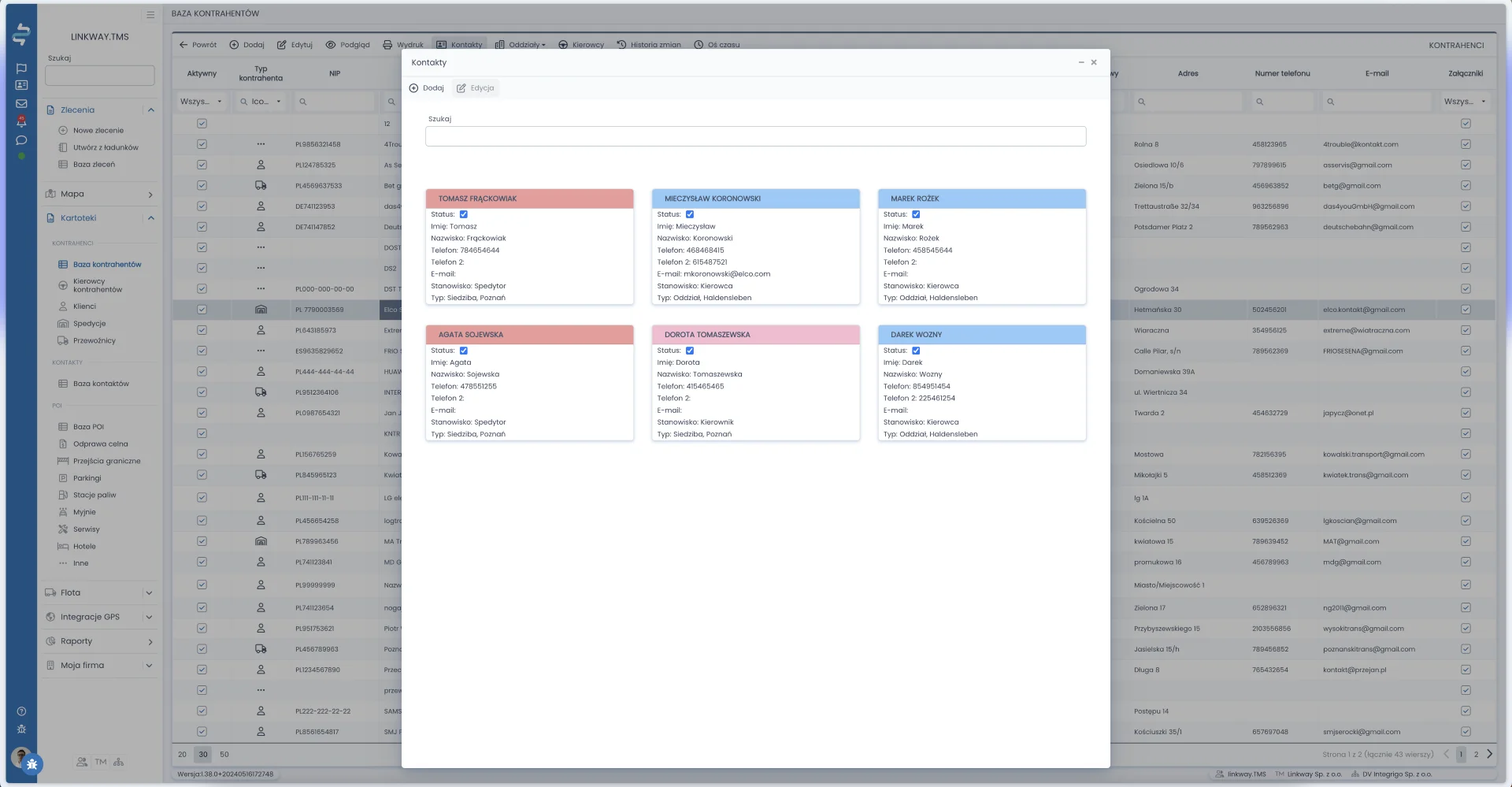

Zarządzanie administracją firmy

Poprzez linkway.INTEGRATOR można przeglądać dane o firmowych użytkownikach systemu, edytować je, weryfikować oraz zmieniać uprawnienia. System pozwala także na kontrolę bilingów i faktur.

Udostępnianie danych

Wybrane informacje dotyczące transportów mogą być udostępniane klientom i zleceniodawcom. W szybki sposób dokonuje się również weryfikacji zasobów udostępnianych partnerom.

KORZYŚCI

Dla przewoźnika

zwiększenie bezpieczeństwa transportu

podniesienie komfortu pracy kierowcy

zmniejszenie kosztów operacyjnych

podniesienie wiarygodności biznesowej

zwiększenie efektywności i wydajności pracy

podniesienie konkurencyjności własnej oferty

polepszenie komunikacji ze zleceniodawcą

automatyzacja procesów

przewaga konkurencyjna

Dla zleceniodawcy

integracja z własnym systemem

automatyczne raportowanie

optymalizacja dostaw

monitorowanie ładunków

zwiększenie efektywności i wydajności pracy

zarządzanie ryzykiem dostawy towaru

polepszenie komunikacji z przewoźnikiem

automatyzacja procesów

przewaga konkurencyjna